Wet SystemInerting

Because nitrogen is an inert gas, it does not react with the metal in a fire sprinkler system. Even in the presence of water, no oxidation or rust will occur.

Nitrogen for Wet Systems

Using Nitrogen for corrosion control is a well established practice for dry and pre-action systems. Taking the same concept of purging out the oxygen, replacing it with nitrogen, and applying it to wet systems leads to similarly great results. Simply pre-filling the wet sprinkler system with high purity nitrogen changes the air pockets to nitrogen pockets.

Research shows that opposed to systems with air pockets, on average systems with 99% nitrogen pockets have an increased life expectancy of: 2.8x

Potter's AquaN₂ Method

The Potter AquaN₂ Kit is designed to quickly and effectively purge oxygenated air from a wet fire protection system and replace it with high purity nitrogen gas. Reducing the oxygen levels in wet fire protection systems is essential in protecting the system from the effects of oxygen related corrosion often found at the air water interface in the fire sprinkler piping.

HowIt Works

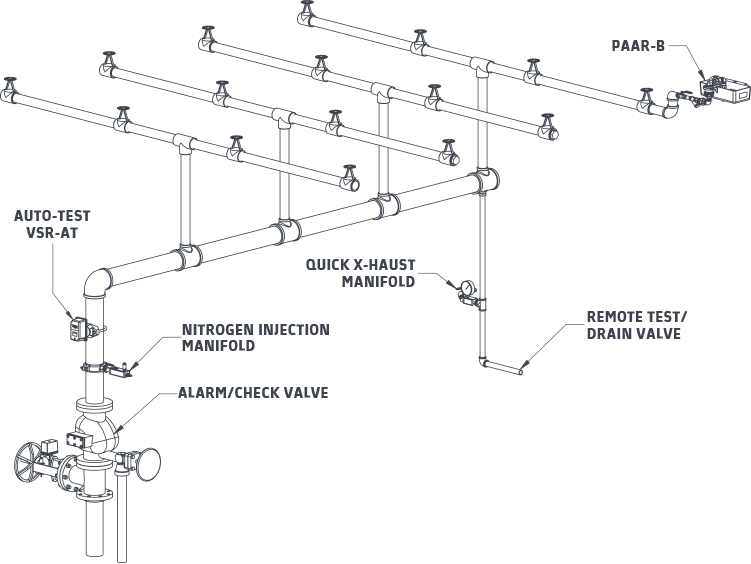

Using the AquaN₂ Kit, which includes the Nitrogen Injection Manifold (NIM) and the Quick X-Haust Manifold (QXM), in combination with a Potter Automatic Air Release (PAAR-B) or Potter Air Vent (PAV) and a nitrogen source, can easily remove up to 99.9% of oxygen from a wet system.

By removing as much air as possible, the fire sprinkler system will have increased performance, eliminating delayed activation or cyclic activation of vane type waterflow detectors.

AquaN₂System

Wet System Inerting Kit

Nitrogen Cylinder Pressure Regulator with Hose

Portable Nitrogen Analyzer

Wet SystemSolutions

Looking for other ways to combat wet system corrosion?

Remove the oxygen

Automatic air vents are the easiest and most cost-effective solution to eliminate trapped air pockets in your sprinkler system.

Potter Air VentsPrevent the introduction of new oxygen

The VSR-AT is a UL Listed and FM Approved flow switch that can be tested without flowing water and introducing new oxygen into the system.

VSR-AT