Wet Pipe Sprinkler Presentation

Wet systems are the most common and reliable types of sprinkler systems. This is because no equipment other than the sprinkler heads are required to operate.

Wet systems use automatic sprinkler heads attached to piping containing water and connected to a water supply. Water will be discharged immediately from an open sprinkler.

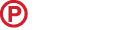

Straight Pipe (Shotgun) Riser

This type of system does not have an alarm check valve. It may have a riser check valve similar to the one shown here.

It has a main pipe, (Riser), being fed directly from the water supply. The Riser goes through a main shut off valve which is usually an OS&Y or Butterfly valve. There will be a 2" main drain immediately above the main control valve. On this drawing, the main drain is part of the riser check valve.

Retard times on the water flow switches are generally set for 30-40 seconds.

The AHJ or engineer may require a different retard time. The retard is needed to prevent false alarms due to water surges. The water flow switch will trip after a continuous flow of at least 10gpm for the length of time the retard is set for.

These systems MUST use a vane [paddle] type of flow switch. There is no way to use a pressure switch on these types of systems.

Potter recommends that the water flow switch be installed at least 24" above the check valve or shut off valve. This is to prevent any turbulence caused by the valves from affecting the operation of the switch.

If the system has a riser check valve similar to the one shown here, there may be two gauges, 1 indicates the supply pressure and the other indicates the system pressure.

The system gauge will usually read higher than the supply gauge, this is because any pressure increases in the supply line should be captured by the check valve, so if the supply pressure drops, the system pressure should stay the same. The system gauge should not go down. If the two gauges always read the same, the check valve may not be holding

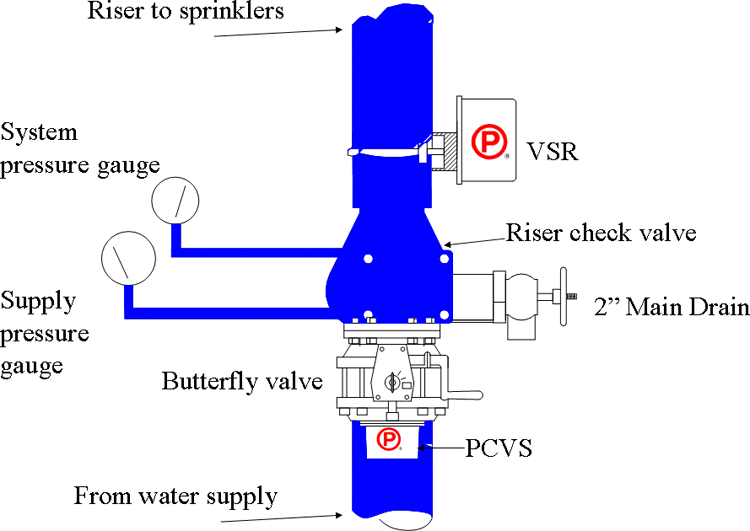

Branch Lines

This represents a typical branch line on a multi story building. The riser comes up and branches off on every floor. There is a shut-off valve for the branch, so that, that section can be shut off if necessary and the rest of the system will remain operational.

There will be a flow switch for each branch line along with test and drain valves.

Frequently the test & drain assembly will be immediately after the flow switch as shown here. Occasionally the test valve will be located at the end of the branch line.

The inspectors test valve is supposed to simulate the smallest sprinkler head on the branch. The valve should also be labeled "INSPECTORS TEST VALVE"

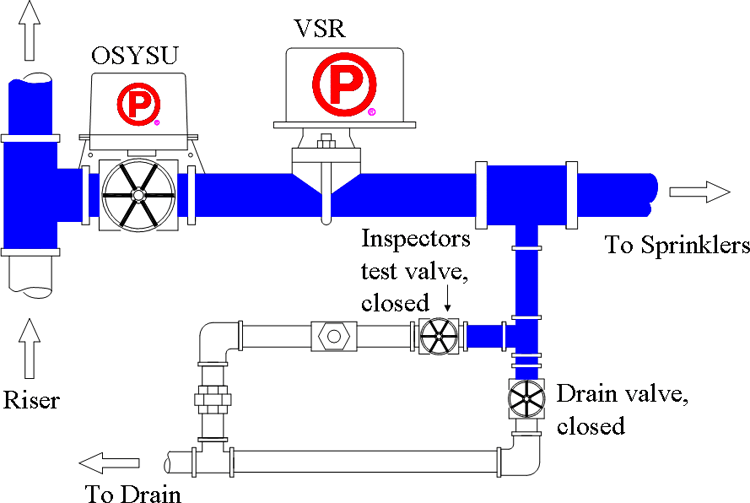

Branch Lines

When the inspectors test valve is opened, it simulates an opening of the smallest sprinkler on that line. If the valve is left open for the amount of time the retard is set for, the flow switch will trip.

There may be a sightglass on the system so that the water can be observed while it is flowing.

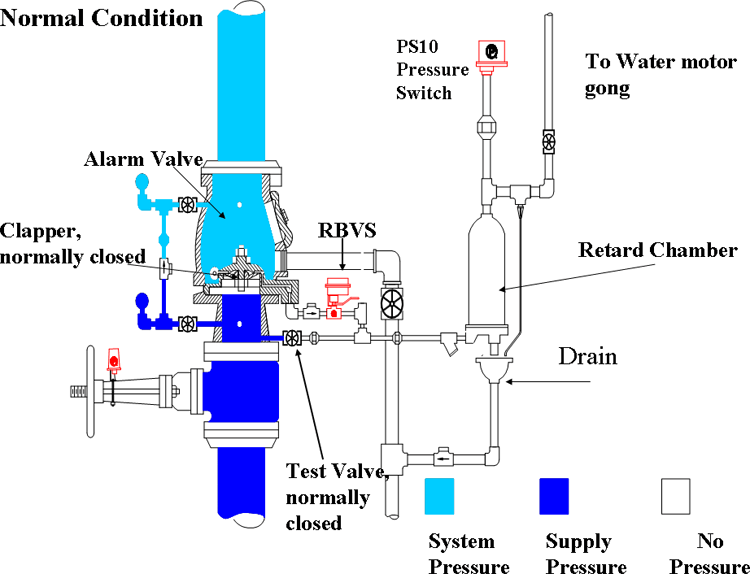

Wet Systems with Alarm Check Valves

There are three ways to monitor for water flow on a system with an alarm valve.

Wet Systems with Alarm Check Valves

(1) A Pressure type flow switch installed on top of a retard chamber:

An alarm check valve is basically a check valve with an alarm port. The main purpose of the alarm check valve is to ring a mechanical bell called a water motor gong. The valve should, (if properly maintained), help hold the system pressure steady and reduce the possibility of false alarms. Under normal circumstances, the clapper of the valve is closed, blocking the alarm port, maintaining the system pressure, and preventing the sprinkler system water from leaking back into the city supply. When a sprinkler opens due to fire, or there is a large surge in the city pressure, the clapper of the valve opens. The alarm port is now exposed to the incoming water supply. When the pressure at the PS10 reaches 6psi, the pressure switch trips.

These systems can use a vane type flow switch with a retard or they can use a pressure type flow switch. The pressure type flow switch would be installed on the alarm port, in line with a water motor gong if one is being used. The pressure switch must be installed on top of a retard chamber to prevent false alarms due to water surges.

Retard chambers are metal containers that fill with water when there is a surge in city pressure. They absorb the pressure increase thereby allowing the pressure switch to only operate in an actual alarm condition.

Wet Systems with Alarm Check Valves

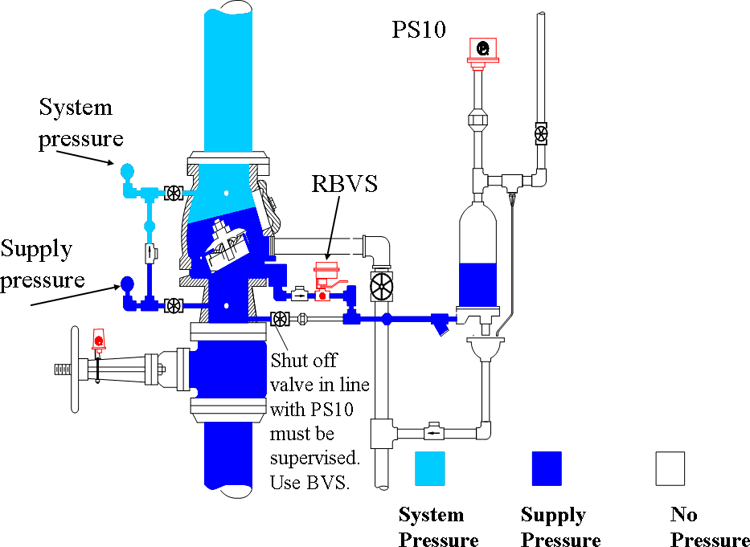

Here the clapper of the valve is opening allowing water to flow into the alarm port, and the retard chamber is starting to fill. If this were just a surge in the supply, the retard chamber would only partially fill. The pressure at the PS10 would not reach 6psi so the device would not trip.

There must be an automatic drain on this line to allow the water to drain and the pressure to drop back to zero so the pressure switch can reset after a surge or activation of the alarm valve.

Since the retard chambers are metal containers that are constantly getting wet and drying out, they require maintenance to make sure that the drain stays clear and doesn't get clogged with rust or corrosion. If a surge does not drain from the retard chamber before another surge happens, the retard chamber may fill causing the pressure switch to send a false alarm.

On the left side of the alarm valve there is a bypass line with a check valve and 2 pressure gauges. This allows small surges to flow through here to build up the system pressure causing excessive wear and tear on the clapper of the alarm valve. The gauges show the system pressure and the supply pressure, The system gauge will usually read higher than the supply gauge, it should never read lower. The 2 gauges will read the same immediately after a surge in supply pressure and until the supply pressure drops back down. If the system gauge drops down with the supply gauge, the clapper of the alarm check valve is not seating properly and needs to be serviced.

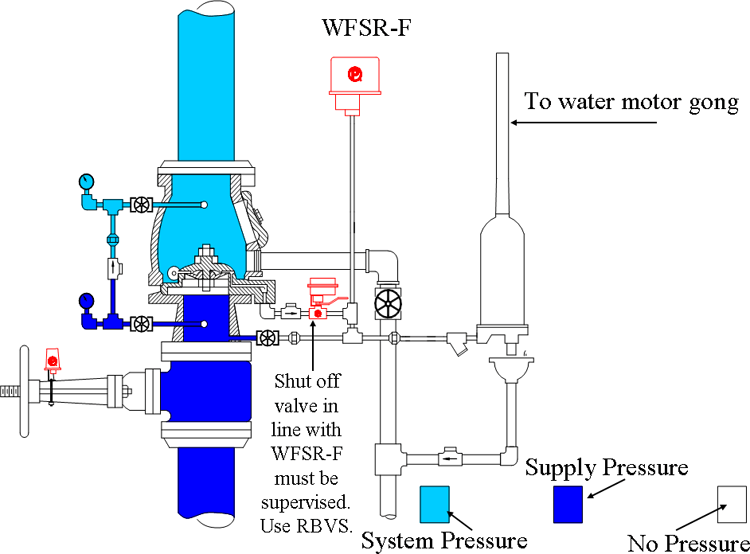

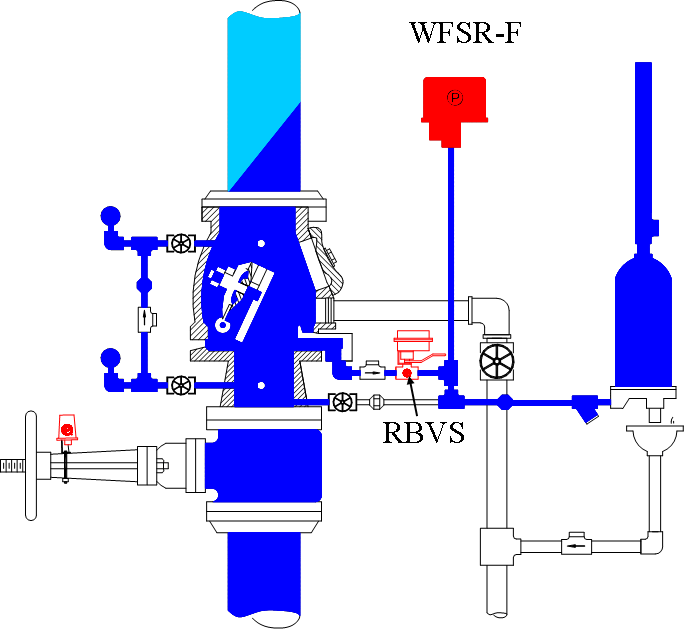

Wet Systems with Alarm Check Valves

(2) A Pressure type flow switch with a built-in retard:

This is the same type of system except this one uses a pressure switch with a built-in retard instead of installing the pressure switch on top of the retard chamber. In this case the retard chamber is only being used to delay the water motor gong. If there is no water motor gong, the retard chamber can be eliminated.

The retard time will start when the pressure at the WFSR-F reaches 6psi. The pressure must remain there for the length of time the retard is set in order for the device to trip.

Pressure type flow switches can be installed without disabling the sprinkler system. Since they are installed on the alarm port, there is no pressure or water present under normal conditions. The sprinkler system does not have to be drained, they can be installed without shutting off the water supply. Therefore, the sprinkler system is never out of service.

A pressure switch with a built-in retard allows the system to remain operational at all times, and eliminates the maintenance required on the retard chamber. An automatic drain is still required to relieve the pressure on the line.

Note: All water control valves should be supervised.

Pressure type flow switches must be installed before any shut off valve, or such valve must be electronically supervised if the sprinkler system is required to be supervised in accordance with NFPA72

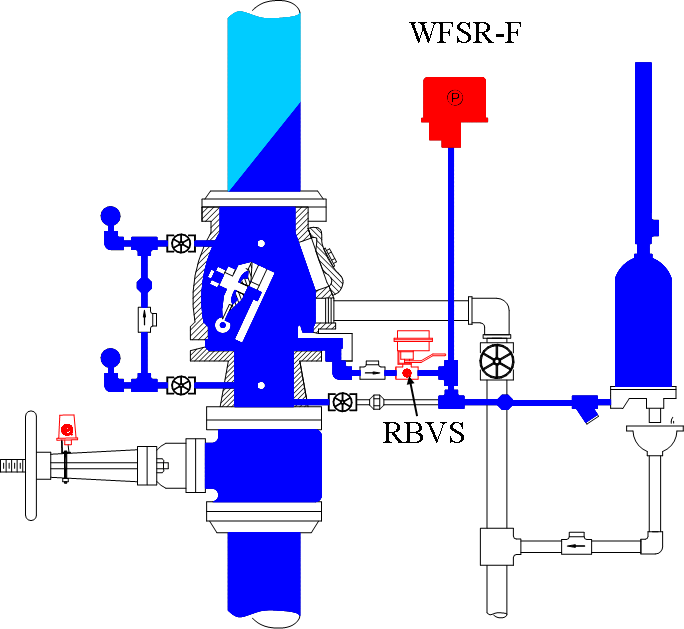

Wet Systems with Alarm Check Valves

Here a sprinkler fused so the alarm valve will remain open due to water flowing from the supply out through the open sprinkler.

The water filled the retard chamber and is being discharged through the water motor gong.

The WFSR-F tripped because there was pressure in the alarm line for the length of time the retard was set.

The BVS is a supervised ball valve that is used as an alarm shutoff valve for the WFSR-F and water motor gong.

Wet Systems with Alarm Check Valves

(3) Vane Type Water Flow Switches:

A vane type flow switch can be used just like on a straight pipe riser system.

However, one of the benefits of the alarm valve is that it allows the waterflow switch to be installed or replaced without draining the sprinkler system. Therefore, the sprinkler system can remain in service while the flow switch is being replaced.

Test valve location

The trim on the alarm valves allows for testing of the pressure type flow switch without flowing water throughout the entire system.

There is an alarm test valve that is connected to the supply water before the alarm valve. When this valve is opened it allows water to flow from the supply to the pressure switches and bells.