One of the keys to assessing the overall health of a dry or preaction fire sprinkler system is to keep an eye on its leak rate. Excessive leak rates can put unnecessary strain on air compressors or nitrogen generators used for supervisory air in these systems. For those systems with air compressors, this can lead to an increase in corrosion since the more the compressor runs, the more oxygenated air is introduced into the system. Leak rates that are shown to be increasing can also signal serious potential problems looming.

Monitoring or testing for leak rates has not always been required, at least not in the prescriptive manner it is today. Prior to the 2008 edition of NFPA 25, Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems, there were no "proactive" requirements to test leak rates on a regular basis. In those early editions of NFPA 25, all that was required was simply to address leaks that were noted to be in excess of 10 psi per week. There was no associated routine test called out by the standard.

Beginning with the 2008 edition of NFPA 25, testing to determine the rate at which dry and preaction systems leak air became a requirement and must be performed on a regular (3-year) frequency. The intent of this testing is to hopefully identify leaks before they become a major problem. The standard allows for two methods of completing this test. One option is to perform a 40 psi pressure test for 2 hours with an acceptable loss of 3 psi. The other is simply shutting off the air supply for 4 hours and if the low pressure alarm activates during that time, the leaks must be addressed.

The Value of Data

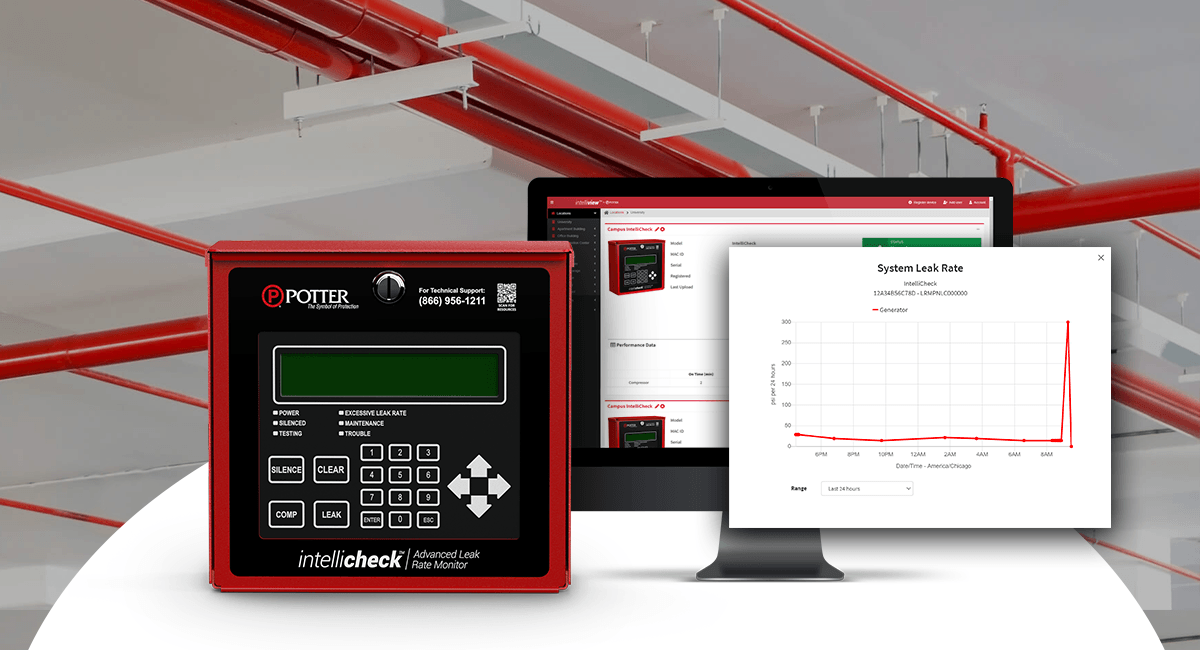

Either of the two test methods permitted by NFPA 25 will provide owners with a high-level indication of how leaky their system may be. But actually capturing the pressure loss data combined with the ability to track changes over time, can provide a much more thorough look into what may be occurring within the system. In addition, having a sense of how often the nitrogen generator or air compressor is running is also important. Among other things, this provides the peace of mind of knowing that the system won't accidentally trip with a short power outage.

Although the NFPA 25 test methods have been proven valuable, performing the actual tests are time-consuming and don't always get performed. And even when the testing does take place, locating data from previous tests to compare to is often difficult. Advances in technology now allow these tests to be completed automatically in some cases, and the all-important data they generate to be captured and stored for later reference. At a minimum, NFPA 25 requires that this information be recorded, and that those records be retained for at least 1 year beyond the next leak rate test.

For more information on Potter's IntelliCheck Advanced Leak Rate Monitor, visit our Information Portal.